Uxinaniso oluPhezulu lweDiameter encinci yeDiameter yeGraphite Electrode yeLadle Furnace Blast Funece ekuNyibilikiseni intsimbi

IParameter yobuGcisa

Itshathi yoku-1:Iparamitha yobuChwephesha kwiDiameter encinci yeGraphite Electrode

| Ububanzi | Icandelo | Ukuchasa | Amandla e-Flexural | Imodulus eselula | Ukuxinana | CTE | Uthuthu | |

| Intshi | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Itshathi yesi-2:Isakhono sokuGqiba sangoku soMbane we-Diameter encinci yeGraphite Electrode

| Ububanzi | Umthwalo wangoku | Ukuxinana kwangoku | Ububanzi | Umthwalo wangoku | Ukuxinana kwangoku | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Itshathi yesi-3: Ubungakanani beGraphite Electrode kunye noNyamezelo kwiDiameter encinci yeGraphite Electrode

| Idayamitha yeNominal | Okwenyani Ububanzi (mm) | Ubude begama | Ukunyamezelana | |||

| Intshi | mm | Max. | Min. | mm | Intshi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Isicelo esingundoqo

- Ukunyibilikiswa kwecalcium carbide

- Imveliso yeCarborund

- Ukucokiswa kweCorundum

- Iintsimbi ezinqabileyo ezinyibilikayo

- Ferrosilicon plant refractory

Umyalelo wokunikezela kunye nokuSetyenziswa kwee-Electrode zegraphite

1.Sebenzisa izixhobo ezikhethekileyo zokuphakamisa ebomini i-electrode yegraphite iphephe ukonakala ngexesha lokuthutha.(jonga i-pic1)

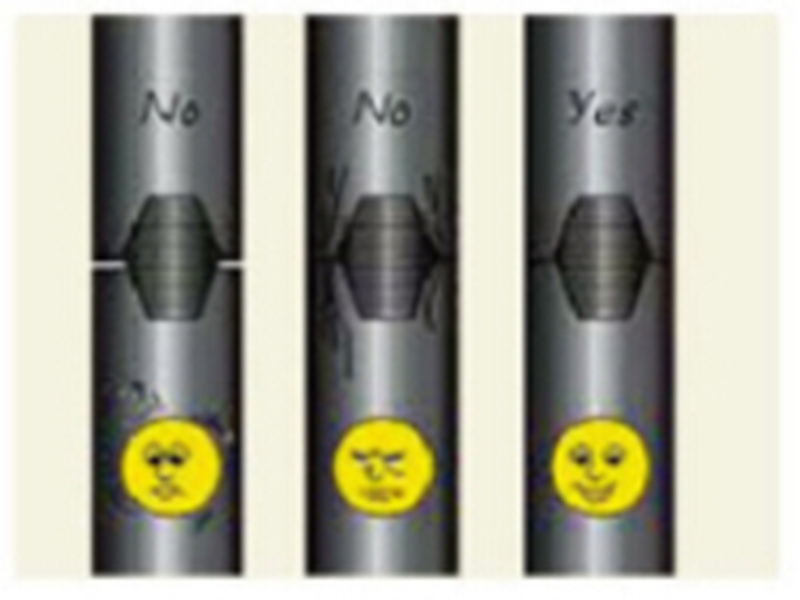

2.I-electrode yegraphite kufuneka igcinwe kude ekubeni ifumiswe okanye imanziswe yimvula, yikhephu, igcinwe yomile.(bona pic2)

3.Ukujonga ngononophelo ngaphambi kokusetyenziswa qinisekisa ukuba i socket kunye nentambo yengono ifanelekile ukusetyenziswa, kubandakanywa nokuhlolwa kwepitch, iplagi.(jonga i-pic3)

4.Coca iingono kunye nemisonto yeziseko ngomoya ocinezelweyo.(jonga i-pic4)

5.Ngaphambi kokusetyenziswa, i-electrode yegraphite kufuneka yomiswe eziko, ubushushu bokumisa kufuneka bube ngaphantsi kwe-150 ℃, ixesha elomileyo kufuneka libe ngaphezu kweeyure ezingama-30. (jonga i-pic5)

6.I-electrode yegraphite kufuneka idityaniswe ngokuqinileyo kwaye ngokuthe tye kunye netorque efanelekileyo yokuqinisa.(jonga i-pic6)

7.Ukuze ugweme ukuphuka kwe-electrode yegraphite, faka inxalenye enkulu kwindawo ephantsi kunye nenxalenye encinci kwindawo ephezulu.