HP24 Graphite Carbon Electrodes Dia 600mm Electrical Arc Furnace

IParameter yobuGcisa

| Ipharamitha | Icandelo | Iyunithi | HP 600mm(24”) Idatha |

| Idayamitha yeNominal | I-Electrode | mm(intshi) | 600 |

| Ubukhulu beDayamitha | mm | 613 | |

| Ububanzi obuncinci | mm | 607 | |

| Ubude begama | mm | 2200/2700 | |

| Max Ubude | mm | 2300/2800 | |

| Min Ubude | mm | 2100/2600 | |

| Ukuxinana kwangoku | KA/cm2 | 13-21 | |

| Umthamo wokuthwala wangoku | A | 38000-58000 | |

| Ukuchasa ngokuthe ngqo | I-Electrode | μΩm | 5.2-6.5 |

| Ingono | 3.2-4.3 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥10.0 |

| Ingono | ≥22.0 | ||

| Imodulus yolutsha | I-Electrode | Gpa | ≤12.0 |

| Ingono | ≤15.0 | ||

| Unizi lolwapho kuyiwa khona | I-Electrode | g/cm3 | 1.68-1.72 |

| Ingono | 1.78-1.84 | ||

| CTE | I-Electrode | ×10-6/℃ | ≤2.0 |

| Ingono | ≤1.8 | ||

| Isiqulatho sothuthu | I-Electrode | % | ≤0.2 |

| Ingono | ≤0.2 |

QAPHELA:Nayiphi na imfuneko ethile yobungakanani inokunikwa.

Indlela yokuTshatisa i-Electrode yeGraphite kunye ne-Electric Arc Furnace

Iielectrode zegraphite ngamacandelo abalulekileyo kwinkqubo yokwenziwa kwentsimbi yoMbane weArc (EAF). Nangona kunjalo, iindleko zenkqubo yokwenza i-steelmaking ichaphazeleka yi-electrode oxidation, i-sublimation, i-dissolution, i-spalling, kunye nokuphuka. Iindaba ezilungileyo kukuba ukhetho lwe-electrode yegraphite, ukusetyenziswa, kunye nokugcinwa kunokunciphisa ngokufanelekileyo ukusetyenziswa kwe-electrode. Kweli nqaku, siza kuxubusha indlela yokukhetha i-electrode eyi-graphite efanelekileyo kunye nendlela yokuyigcina ngokufanelekileyo ukuze ufumane ubuninzi botyalo-mali lwakho.

Iinkcukacha

Ukuhambelana phakathi komthamo wesithando sombane, umthwalo wamandla we-transformer kunye nobukhulu be-electrode.

| Isithando soMbane | Ububanzi obungaphakathi (m) | Umthamo wokuGuqulela (MVA) | I-Graphite Electrode Diameter (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

Umyalelo wokuSasa kunye nokuSetyenziswa

- 1.Susa isigqubuthelo sokukhusela somngxuma omtsha we-electrode, khangela ukuba intambo kwi-electrode hole iphelile kwaye intambo ayiphelelanga, qhagamshelana neenjineli zobuchwephesha ukugqiba ukuba i-electrode ingasetyenziswa;

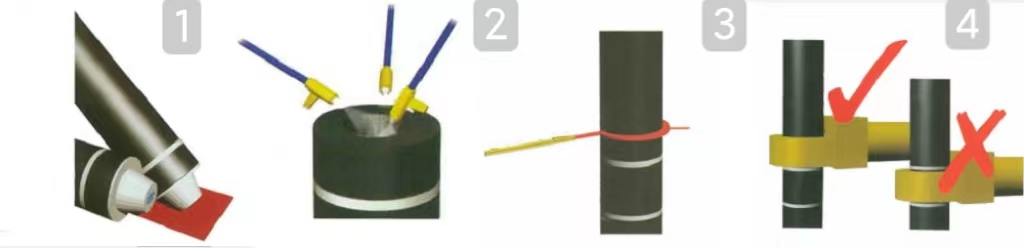

- 2.Khipha i-electrode hanger kwi-electrode hole kwelinye icala, kwaye ubeke i-cushion ethambileyo phantsi kwesinye isiphelo se-electrode ukuze ugweme ukulimaza i-electrode joint; (jonga umfanekiso1)

- 3.Sebenzisa umoya oxinyiweyo ukuvuthela uthuli kunye ne-sundries ebusweni kunye nomngxuma we-electrode yokudibanisa, uze uhlambulule umphezulu kunye nesixhumi se-electrode entsha, uhlambulule nge-brush; (jonga umfanekiso 2)

- 4.Phakamisa i-electrode entsha ngaphezu kwe-electrode elindileyo ukulungelelanisa nomngxuma we-electrode kwaye uwe kancinci;

- 5.Sebenzisa ixabiso elifanelekileyo letorque ukuvala i-electrode ngokufanelekileyo; (Jonga umfanekiso wesi3)

- 6.Umphathi we-Clamp kufuneka abekwe ngaphandle komgca we-alamu. (Jonga kwipic4)

- 7.Ngexesha lokucoca, kulula ukwenza i-electrode ibe yincinci kwaye ibangele ukuphuka, ukuwa ngokubambisana, ukwandisa ukusetyenziswa kwe-electrode, nceda ungasebenzisi i-electrodes ukuphakamisa umxholo wekhabhoni.

- 8.Ngenxa yezixhobo ezahlukeneyo ezisetyenziswa ngumenzi ngamnye kunye nenkqubo yokuvelisa, iimpawu ezibonakalayo kunye neekhemikhali ze-electrode kunye namalungu omenzi ngamnye. Ke ekusetyenzisweni, phantsi kweemeko ngokubanzi, Nceda ungaxubi ukusebenzisa i-electrodes kunye namalungu aveliswe ngabavelisi abohlukeneyo.