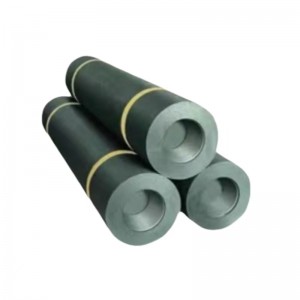

I-Furnace Graphite Electrode Amandla aQhakamkileyo RP iBanga le-550mm iDiameter enkulu

IParameter yobuGcisa

| Ipharamitha | Icandelo | Iyunithi | RP 550mm(22”) Idatha |

| Idayamitha yeNominal | I-Electrode | mm(intshi) | 550 |

| Ubukhulu beDayamitha | mm | 562 | |

| Ububanzi obuncinci | mm | 556 | |

| Ubude begama | mm | 1800/2400 | |

| Max Ubude | mm | 1900/2500 | |

| Min Ubude | mm | 1700/2300 | |

| Ubuninzi bangoku | KA/cm2 | 12-15 | |

| Umthamo wokuthwala wangoku | A | 28000-36000 | |

| Ukuchasa ngokuthe ngqo | I-Electrode | μΩm | 7.5-8.5 |

| Ingono | 5.8-6.5 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥8.5 |

| Ingono | ≥16.0 | ||

| Imodulus yolutsha | I-Electrode | Gpa | ≤9.3 |

| Ingono | ≤13.0 | ||

| Unizi lolwapho kuyiwa khona | I-Electrode | g/cm3 | 1.55-1.64 |

| Ingono | |||

| CTE | I-Electrode | ×10-6/℃ | ≤2.4 |

| Ingono | ≤2.0 | ||

| Isiqulatho sothuthu | I-Electrode | % | ≤0.3 |

| Ingono | ≤0.3 |

QAPHELA:Nayiphi na imfuneko ethile yobungakanani inokunikwa.

IiFactors ze-Electrode zeGraphite kwi-Steelmaking

Kwishishini le-steelmaking, inkqubo ye-Electric Arc Furnace (EAF) yenye yezona ndlela zisetyenziswa kakhulu. Ukukhetha i-electrode efanelekileyo yegraphite ibalulekile kule nkqubo. I-RP (Amandla aqhelekileyo) i-electrode yegraphite lukhetho oludumileyo ngenxa yokufikeleleka kunye nokufaneleka kwemisebenzi yesithando somlilo esiphakathi.

Xa ukhetha i-electrode yegraphite yeRP, kukho izinto ezininzi ezibalulekileyo ekufuneka ziqwalaselwe. Enye i-diameter ye-electrode, ekufuneka ifanele ubungakanani obuthile besithando somlilo kunye neemfuno zokuvelisa. Ibakala le-electrode yenye into; I-RP graphite electrode idla ngokuhlelwa ngokwamabakala amane ngokokumelana nombane kunye namandla aguquguqukayo. Ibakala elifanelekileyo kufuneka likhethwe ngokusekelwe kwiimfuno ezithile zokusebenza kwesithando somlilo.

Idatha eCetyisiweyo yokuMatanisa i-Electrode yeGraphite kunye ne-Electric Arc Furnace

| Umthamo weziko (t) | Ububanzi obungaphakathi (m) | Umthamo wokuGuqulela (MVA) | I-Graphite Electrode Diameter (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

UMlawuli woMgangatho womphezulu

I-1.Iziphene okanye imingxuma akufanele ibe ngaphezu kweengxenye ezimbini kwi-graphite electrode surface, kwaye iziphene okanye ubungakanani bemingxuma akuvumelekanga ukudlula idatha kwitheyibhile ekhankanywe ngezantsi.

2.Akukho qhekeko olunqamlezayo kumphezulu we-electrode.Ngokuqhekeka kwe-longitudinal, ubude bayo kufuneka bungabi ngaphezu kwe-5% yesangqa se-electrode yegraphite, ububanzi bayo bube ngaphakathi kwe-0.3-1.0mm uluhlu.Idatha yokuqhekeka kweLongitudinal ngezantsi kwe-0.3mm idatha kufuneka ungahoywa

3. Ububanzi bendawo erhabaxa (emnyama) kumphezulu we-electrode yegraphite kufuneka bungabi ngaphantsi kwe-1/10 yesangqa se-electrode yegraphite, kunye nobude bendawo erhabaxa (emnyama) ngaphezulu kwe-1/3 yobude be-electrode yegraphite. ayivumelekanga.

Idatha yeSiphene soMphezulu weTshati yeGraphite Electrode

| Idayamitha yeNominal | Idatha yesiphene(mm) | ||

| mm | intshi | Ububanzi (mm) | Ubunzulu(mm) |

| 300-400 | 12-16 | 20–40 | 5–10 |

| 450-700 | 18-24 | 30–50 | 10–15 |