I-RP 600mm 24inch yeGraphite Electrode ye-EAF LF Intsimbi yokunyibilikisa

IParameter yobuGcisa

| Ipharamitha | Icandelo | Iyunithi | RP 600mm(24”) Idatha |

| Idayamitha yeNominal | I-Electrode | mm(intshi) | 600 |

| Ubukhulu beDayamitha | mm | 613 | |

| Ububanzi obuncinci | mm | 607 | |

| Ubude begama | mm | 2200/2700 | |

| Max Ubude | mm | 2300/2800 | |

| Min Ubude | mm | 2100/2600 | |

| Ubuninzi bangoku | KA/cm2 | 11-13 | |

| Umthamo wokuthwala wangoku | A | 30000-36000 | |

| Ukuchasa ngokuthe ngqo | I-Electrode | μΩm | 7.5-8.5 |

| Ingono | 5.8-6.5 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥8.5 |

| Ingono | ≥16.0 | ||

| Imodulus yolutsha | I-Electrode | Gpa | ≤9.3 |

| Ingono | ≤13.0 | ||

| Unizi lolwapho kuyiwa khona | I-Electrode | g/cm3 | 1.55-1.64 |

| Ingono | ≥1.74 | ||

| CTE | I-Electrode | ×10-6/℃ | ≤2.4 |

| Ingono | ≤2.0 | ||

| Isiqulatho sothuthu | I-Electrode | % | ≤0.3 |

| Ingono | ≤0.3 |

QAPHELA:Nayiphi na imfuneko ethile yobungakanani inokunikwa.

Indlela yoLondolozo lweGraphite Electrode

Ukongeza kokukhetha i-electrode ye-graphite echanekileyo yeRP, ukugcinwa kubalulekile ukuqinisekisa ixesha elide kunye nokusebenza kakuhle kwe-electrode. Ukuphathwa ngokufanelekileyo kunye nokugcinwa kwe-electrode kubalulekile ukunciphisa umngcipheko we-electrode oxidation, i-sublimation, i-dissolution, i-spalling, kunye nokuphuka. Xa i-electrode isetyenzisiweyo, umqhubi wesithando somlilo kufuneka ahlawule ingqalelo kwi-electrode yokugqoka kunye nokukrazula kunye nokulungelelanisa indawo ye-electrode kunye negalelo lamandla ngokufanelekileyo. Ukuhlolwa okufanelekileyo emva kokugcinwa, kubandakanywa nokuhlolwa okubonakalayo kunye nokuhlolwa kombane wokuqhuba umbane, kunokunceda kwakhona ukuchonga nawuphi na umonakalo onokwenzeka okanye ukuwohloka kwe-electrode.

Umyalelo wokunikezela kunye nokuSetyenziswa kwee-Electrode zegraphite

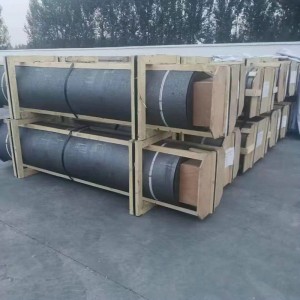

- Sebenzisa izixhobo zokuphakamisa ezikhethekileyo ebomini i-electrode yegraphite uphephe ukonakala ngexesha lokuhamba.(jonga i-pic1)

- I-electrode yegraphite kufuneka igcinwe kude ekubeni ifumiswe okanye imanziswe yimvula, yikhephu, igcinwe yomile.(bona pic2)

- Ukujonga ngononophelo ngaphambi kokusetyenziswa qinisekisa ukuba isokhethi kunye nentambo yengono ikulungele ukusetyenziswa, kubandakanywa nokuhlolwa kwepitch, iplagi.(bona pic3)

- Coca iingono kunye nemisonto yeziseko ngomoya ocinezelweyo.(jonga i-pic4)

- Ngaphambi kokusetyenziswa, i-electrode yegraphite kufuneka yomiswe eziko, ubushushu bokomisa kufuneka bube ngaphantsi kwe-150 ℃, ixesha elomileyo kufuneka libe ngaphezu kweeyure ezingama-30. (jonga i-pic5)

- I-electrode yegraphite kufuneka idityaniswe ngokuqinileyo kwaye ngokuthe tye kunye netorque efanelekileyo yokuqinisa. (jonga i-pic6)

- Ukunqanda ukuqhekeka kwe-electrode yegraphite, beka indawo enkulu kwindawo esezantsi kunye nenxalenye encinci kwindawo ephezulu.

Itshathi ye-RP yeGraphite Electrode yangoku eGqobayo

| Idayamitha yeNominal | Amandla aqhelekileyo (RP) kwiBanga leGraphite Electrode | ||

| mm | Intshi | Umthamo wokuthwala wangoku(A) | Uxinano lwangoku(A/cm2) |

| 300 | 12 | 10000-13000 | 14-18 |

| 350 | 14 | 13500-18000 | 14-18 |

| 400 | 16 | 18000-23500 | 14-18 |

| 450 | 18 | 22000-27000 | 13-17 |

| 500 | 20 | 25000-32000 | 13-16 |

| 550 | 22 | 28000-36000 | 12-15 |

| 600 | 24 | 30000-36000 | 11-13 |