I-Diameter encinci ye-Electrodes ye-Electrodes ye-Electrodes yoMbane ye-Arc yoMbane yeNsimbi kunye ne-Foundry Industry

IParameter yobuGcisa

Itshathi yoku-1:Iparamitha yobuChwephesha kwiDiameter encinci yeGraphite Electrode

| Ububanzi | Icandelo | Ukuchasa | Amandla e-Flexural | Imodulus eselula | Ukuxinana | CTE | Uthuthu | |

| Intshi | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Itshathi yesi-2:Isakhono sokuGqiba sangoku soMbane we-Diameter encinci yeGraphite Electrode

| Ububanzi | Umthwalo wangoku | Ukuxinana kwangoku | Ububanzi | Umthwalo wangoku | Ukuxinana kwangoku | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Iingenelo

Unyango lwe-1.Anti-oxidation yokuphila ixesha elide.

2.Ubunyulu obuphezulu, ubuninzi obuphezulu, uzinzo oluqinileyo lweekhemikhali.

3.Ukuchaneka okuphezulu komatshini, ukugqitywa komgangatho olungileyo.

4.Amandla aphezulu oomatshini, ukuxhathisa umbane ophantsi.

5.Ukumelana nokuqhekeka kunye nokutshiza.

6.Ukuchasana okuphezulu kwi-oxidation kunye nokutshatyalaliswa kwe-thermal.

Isicelo esingundoqo

- Ukunyibilikiswa kwecalcium carbide

- Imveliso yeCarborund

- Ukucokiswa kweCorundum

- Iintsimbi ezinqabileyo ezinyibilikayo

- Ferrosilicon plant refractory

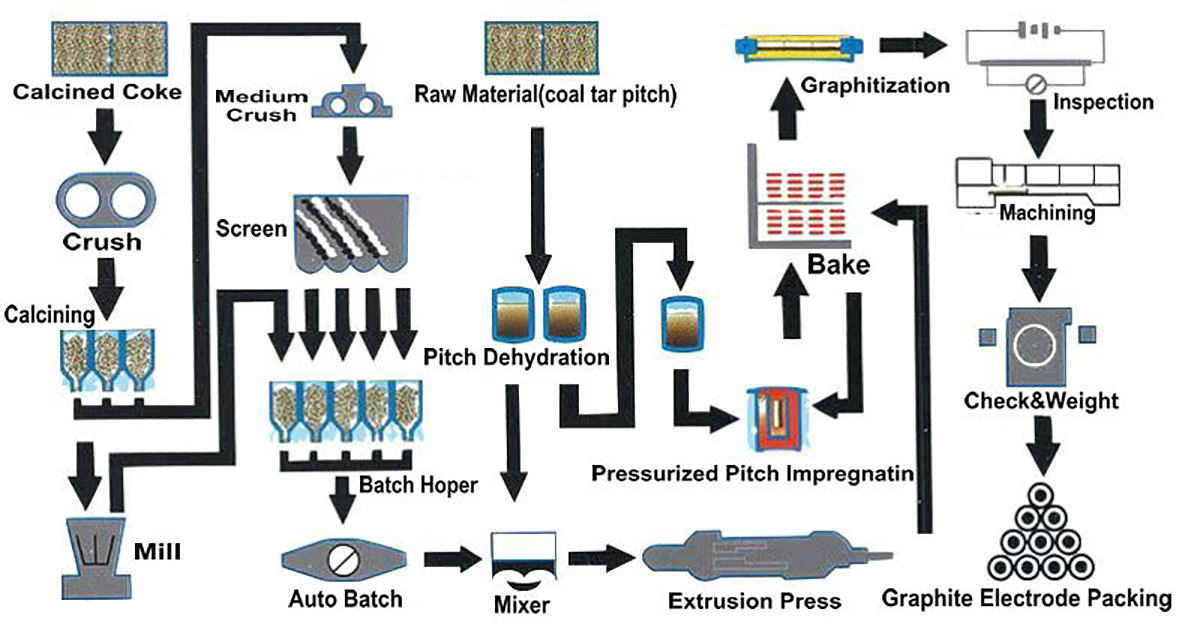

Inkqubo ye-RP Graphite Electrode Production

UMlawuli woMgangatho womphezulu

I-1.Iziphene okanye imingxuma akufanele ibe ngaphezu kweengxenye ezimbini kwi-graphite electrode surface, kwaye iziphene okanye ubungakanani bemingxuma akuvumelekanga ukudlula idatha kwitheyibhile ekhankanywe ngezantsi.

2.Akukho qhekeko olunqamlezayo kumphezulu we-electrode.Ngokuqhekeka kwe-longitudinal, ubude bayo kufuneka bungabi ngaphezu kwe-5% yesangqa se-electrode yegraphite, ububanzi bayo bube ngaphakathi kwe-0.3-1.0mm uluhlu.Idatha yokuqhekeka kweLongitudinal ngezantsi kwe-0.3mm idatha kufuneka ungahoywa

3. Ububanzi bendawo erhabaxa (emnyama) kumphezulu we-electrode yegraphite kufuneka bungabi ngaphantsi kwe-1/10 yesangqa se-electrode yegraphite, kunye nobude bendawo erhabaxa (emnyama) ngaphezulu kwe-1/3 yobude be-electrode yegraphite. ayivumelekanga.