I-Graphite Electrodes Nipples 3tpi 4tpi Connecting Pin T3l T4l

Inkcazo

Ingono ye-electrode yegraphite yinxalenye encinci kodwa iyimfuneko yenkqubo yokwenza intsimbi ye-EAF. Iyinxalenye ye-cylindrical-shaped edibanisa i-electrode kwisithando somlilo. Ngexesha le-steelmaking process, i-electrode iyancipha kwisithando somlilo kwaye idibene nentsimbi etyhidiweyo. Umsinga wombane uhamba nge-electrode, uvelisa ubushushu, obunyibilikisa isinyithi esithandweni. Ingono idlala indima ebalulekileyo ekugcineni unxibelelwano lombane oluzinzileyo phakathi kwe-electrode kunye nesithando somlilo.

IParameter yobuGcisa

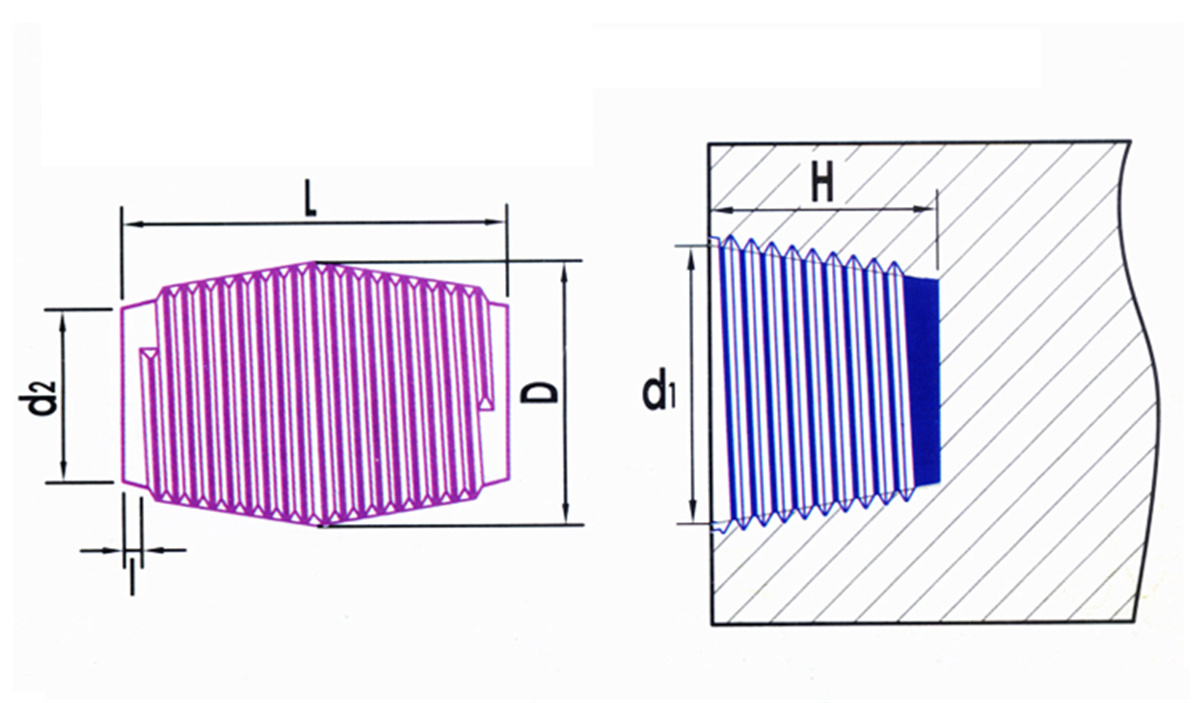

I-Gufan Carbon Conical Nipple kunye neSocket Drawing

| Idayamitha yeNominal | Ikhowudi ye-IEC | Ubungakanani bengono (mm) | Ubungakanani besokethi(mm) | I-pitch | |||||

| mm | intshi | D | L | d2 | I | d1 | H | mm | |

| Ukunyamezelana (-0.5~0) | Ukunyamezela (-1~0) | Ukunyamezela (-5~0) | Ukunyamezela (0~0.5) | Ukunyamezela (0~7) | |||||

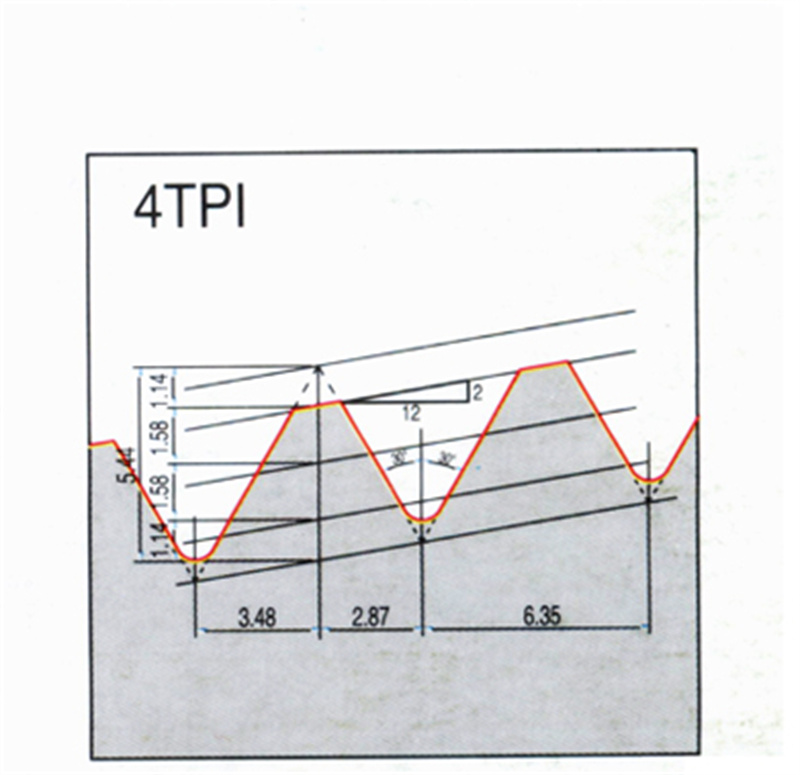

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355.60 | 558.80 | 249.66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | ||

| Idayamitha yeNominal | Ikhowudi ye-IEC | Ubungakanani bengono (mm) | Ubungakanani besokethi(mm) | I-pitch | |||||

| mm | intshi | D | L | d2 | I | d1 | H | mm | |

| Ukunyamezelana (-0.5~0) | Ukunyamezela (-1~0) | Ukunyamezela (-5~0) | Ukunyamezela (0~0.5) | Ukunyamezela (0~7) | |||||

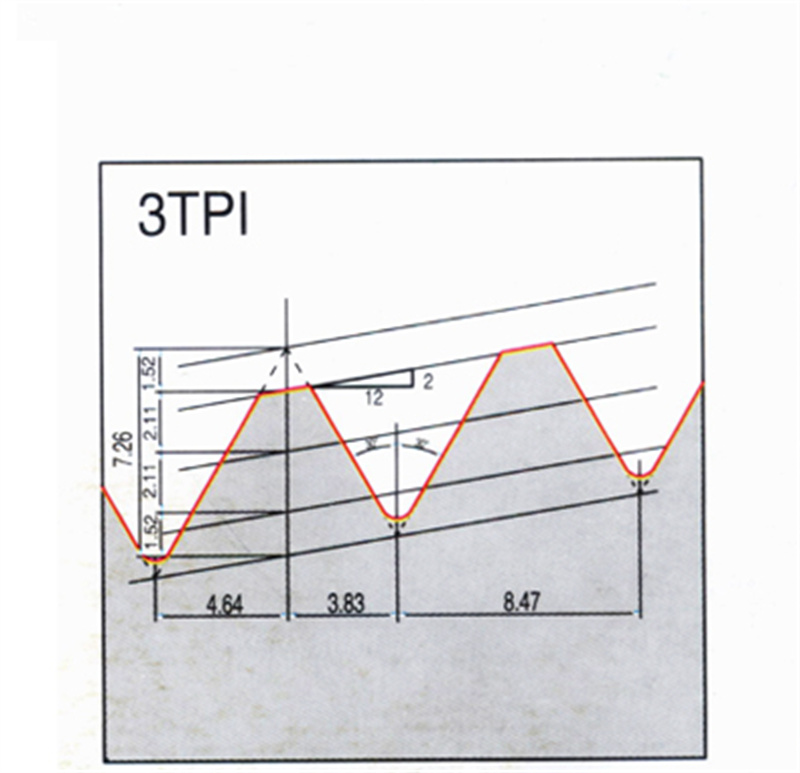

| 250 | 10 | 155T3N | 155.57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| I-Electrode | Ubunzima obuMgangatho beeNgono | ||||||||

| Ubungakanani boMbane we-Electrode | 3TPI | 4TPI | |||||||

| Ububanzi × Ubude | T3N | T3L | T4N | T4L | |||||

| intshi | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Electrode Diameter | intshi | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Umzuzu wokuphumla | N·m | 200–260 | 300–340 | 400–450 | 550–650 | 800–950 |

| Electrode Diameter | intshi | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Umzuzu wokuphumla | N·m | 900–1100 | 1100–1400 | 1500-2000 | 1900–2500 | 2400–3000 |

Umyalelo woFakelo

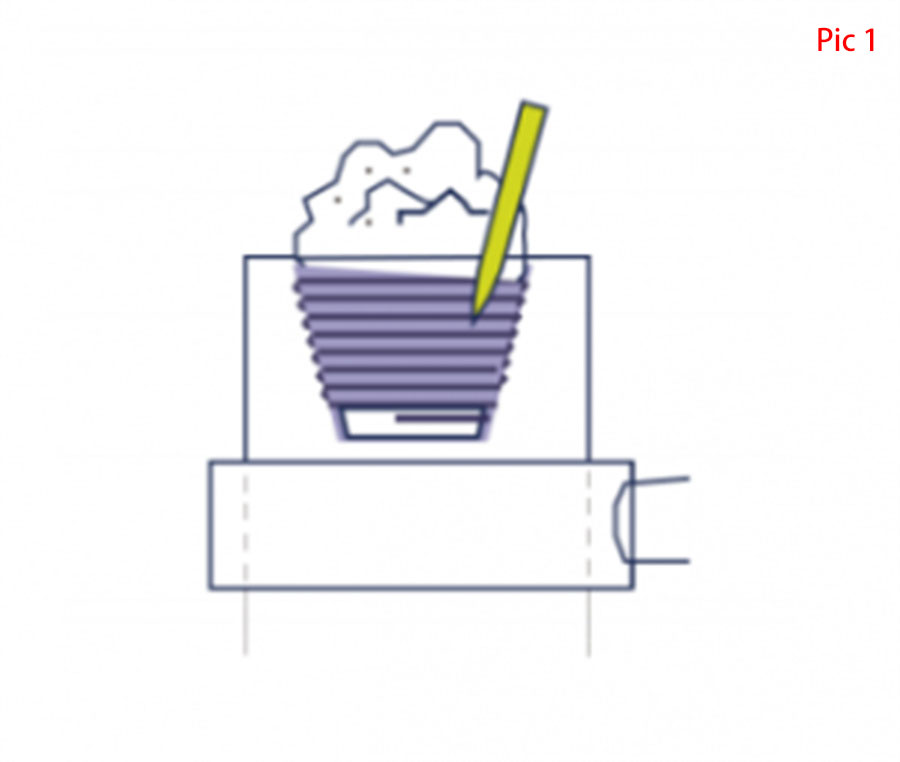

- Ngaphambi kokufaka i-graphite electrode nipple, Coca uthuli kunye nokungcola kumphezulu kunye nesokethi ye-electrode kunye nengono enomoya oxinanisiweyo; (jonga umfanekiso1)

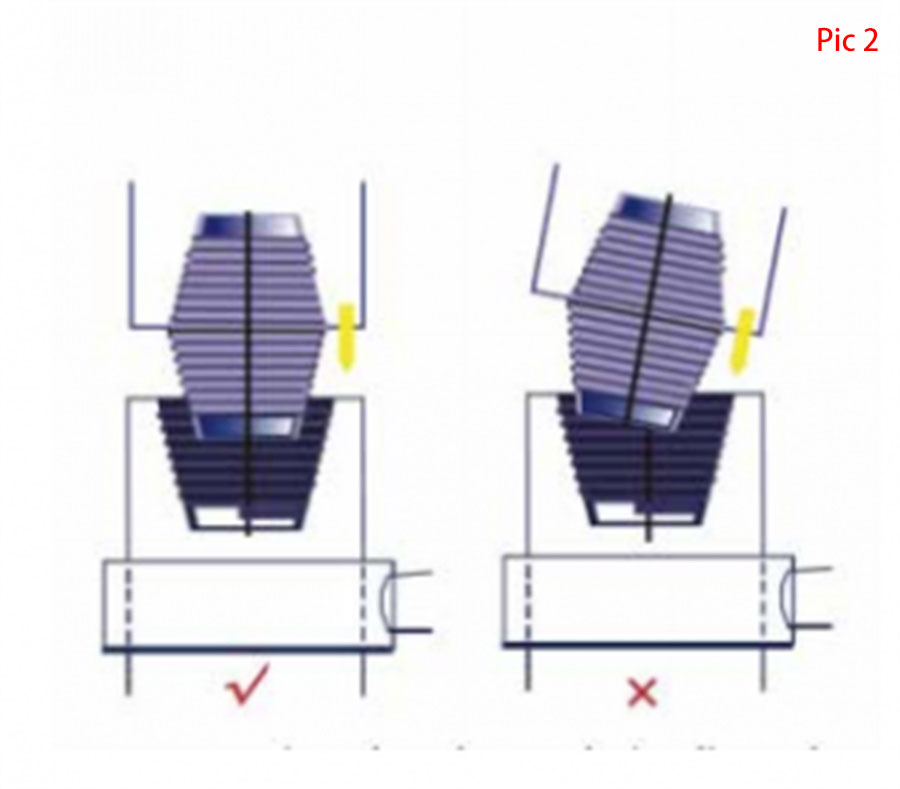

- Umgca ophakathi wengono ye-electrode yegraphite kufuneka igcinwe ihambelana ngexesha lamaqhekeza amabini e-electrode edibeneyo kunye; (jonga umfanekiso 2)

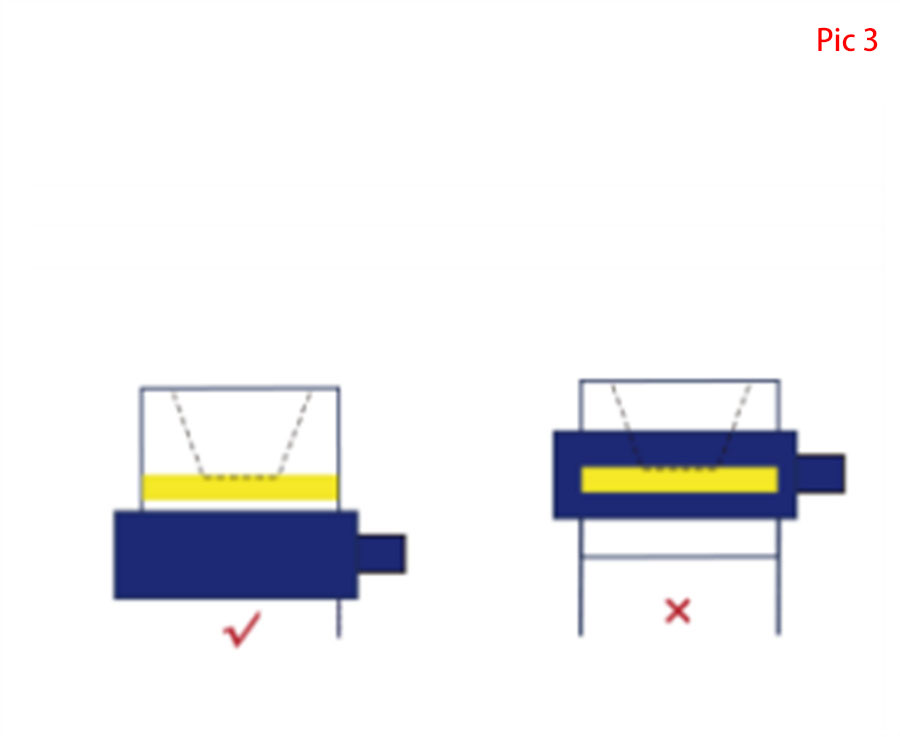

- I-electrode clamper kufuneka ibambe kwindawo efanelekileyo: ngaphandle kwemigca yokhuseleko yesiphelo esiphezulu; (Jonga umfanekiso wesi3)

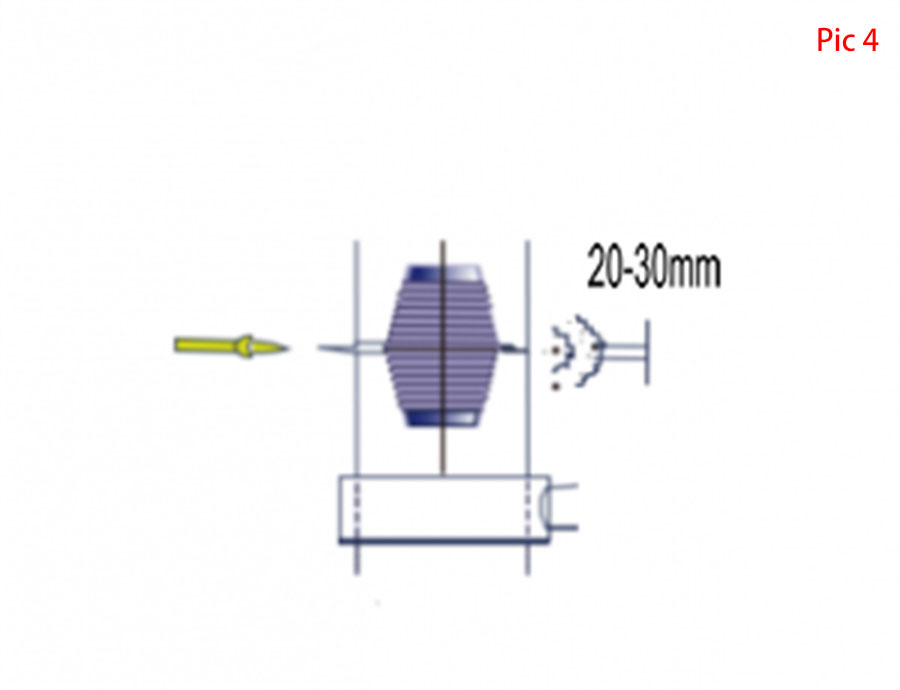

- Phambi kokuqinisa ingono, qinisekisa ukuba umphezulu wengono ucocekile ngaphandle kothuli okanye umdaka. (Jonga kwipic4)

Ingono ye-electrode yegraphite licandelo elibalulekileyo kwinkqubo yokwenza intsimbi ye-EAF. Umgangatho wayo uchaphazela ngokuthe ngqo ukusebenza kunye nokuthembeka kwenkqubo. Ukusebenzisa iingono ezikumgangatho ophezulu kubalulekile ekuthinteleni iingozi ze-electrode kunye nokuqinisekisa inkqubo yokwenza intsimbi egudileyo nevelisayo.Ngokutsho kwedatha yoshishino, ngaphezu kwe-80% yeengozi ze-electrode zibangelwa ziingono ezaphukileyo kunye nokukhubeka okuxekethileyo. Ukukhetha ingono efanelekileyo, le miba ingezantsi kufuneka iqwalaselwe.

- I-Thermal conductivity

- Ukumelana nombane

- Ukuxinana

- Amandla omatshini

Xa ukhetha ingono ye-electrode yegraphite, kubalulekile ukuqwalasela umgangatho wayo, ubungakanani, kunye nokumila kwayo, kunye nokuhambelana ne-electrode kunye neenkcukacha zesithando somlilo. Ngokukhetha ingono efanelekileyo, abavelisi banokuphucula umgangatho wabo wentsimbi kunye nokunciphisa iindleko ezinxulumene nexesha lokunciphisa kunye nokuvelisa kakubi.

Kubandakanya ukuhanjiswa kwayo kwe-thermal, ukumelana nombane, ukuxinana, kunye namandla omatshini.