Inkqubo yeMveliso yeGraphite Electrode

I-electrode yegraphite luhlobo lobushushu obuphezulu obunganyangekiyo kwi-graphite material conductive eveliswa ngokusebenzisa i-petroleum coke, inaliti ye-coke njenge-aggregate, i-asphalt yamalahle njenge-binder, emva koluhlu lweenkqubo ezifana nokuxuba, ukubumba, ukutshisa, ukudipha, i-graphitization kunye nokucubungula oomatshini.

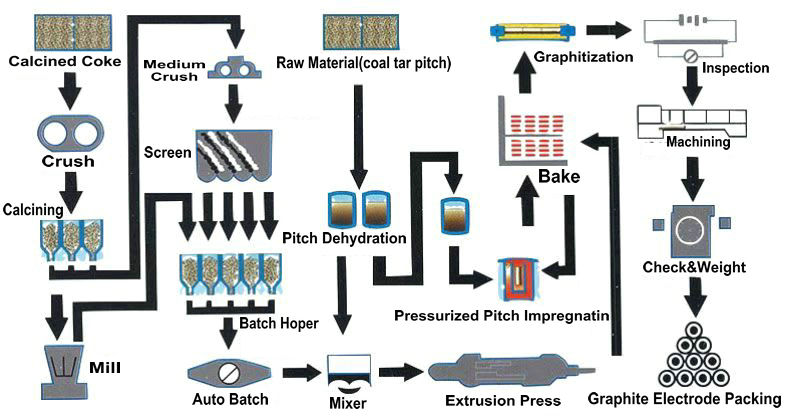

Iinkqubo eziphambili zemveliso ye-electrode yegraphite zezi zilandelayo:

(1) Ukubala.I-petroleum coke okanye i-asphalt coke kufuneka yenziwe, kwaye ubushushu be-calcination kufuneka bufikelele kwi-1300 ℃, ngoko ke ukuze kususwe ngokupheleleyo umxholo oguquguqukayo oqulethwe kwi-carbon eluhlaza, kunye nokuphucula ukuxinana kokwenene, amandla omatshini kunye nokuhanjiswa kombane kwe-coke.

(2) ukutyumza, ukuhluzwa, kunye nezithako.I-calcined carbon raw materials yaphulwa kwaye ihlolwe kwiinqununu ezidibeneyo zobukhulu obuchaziweyo, inxalenye ye-coke igaywe ibe ngumgubo ococekileyo, kwaye umxube owomileyo ugxininiswe ngokwefomula.

(3) Xuba.Kwimeko yokufudumeza, umxube owomileyo wobungakanani bamaqhekeza ahlukeneyo axutywe kunye ne-binder yobuninzi, exutywe kwaye ixotshiwe ukuze idibanise i-plastic paste.

(4) ukubumba, phantsi kwesenzo soxinzelelo lwangaphandle (i-extrusion forming) okanye phantsi kwesenzo se-vibration ephezulu (i-vibration forming) ukucofa unamathisele kwimilo ethile kunye nokuxinana okuphezulu kwe-electrode eluhlaza (billet).

(5) Ukubhaka.I-electrode eluhlaza ifakwe kwisithando somlilo esikhethekileyo, kwaye i-coke powder ye-metallurgical izaliswe kwaye ihlanganiswe ne-electrode eluhlaza.Kubushushu obuphezulu be-agent edibeneyo malunga ne-1250 ℃, i-carbon electrode eyosiweyo yenziwe.

(6) Emsulwa.Ukuze kuphuculwe ukuxinana kunye namandla omatshini weemveliso ze-electrode, i-electrode yokutshisa ilayishwa kwisixhobo sombane ophezulu, kwaye i-agent ye-agent edipha i-asphalt icinezelwe kumngxuma womoya we-electrode.Emva kokucwiliswa, ukutshisa kufuneka kuqhutywe kanye.Ngokweemfuno zokusebenza kwemveliso, ngamanye amaxesha ukufakelwa kunye nokutshisa okwesibini kufuneka kuphindwe ngamaxesha angama-23.

(7) ukwenza umzobo.I-carbon electrode ebhakiweyo ilayishwe kwisithando somlilo se-graphitization, ehlanganiswe ngezinto zokugquma.Ngokusebenzisa indlela yokufudumala yombane othe ngqo ukuvelisa ukushisa okuphezulu, i-carbon electrode iguqulwa ibe yi-graphite electrode kunye ne-graphite crystal structure kwiqondo lokushisa eliphezulu le-2200 ~ 3000 ℃.

(8) ukwenza oomatshini.Ngokweemfuno zokusetyenziswa, igraphite electrode blank surface turning, flat end surface kunye nemingxuma yezikrufu ukwenzela ukusetyenzwa koqhagamshelo, kunye nejoyinti yokudibanisa.

(9) I-electrode yegraphite iya kupakishwa ngokufanelekileyo emva kokugqithisa ukuhlolwa kwaye ithunyelwe kumsebenzisi.

Ixesha lokuposa: Jun-01-2023